The injection molding division of KB.TECH is equipped with a modern, fully standardized production system following Korean quality requirements. Our facility is optimized for producing high-precision electronic components, particularly those used in smartphones and tablets.

1. Equipment Overview

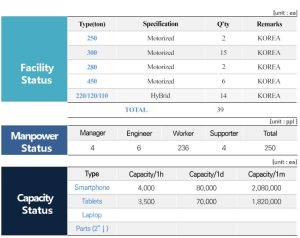

The plant operates a total of 39 injection molding machines with various tonnage capacities, enabling flexible production for a wide range of components:

| Capacity (ton) | Type | Quantity | Origin |

|---|---|---|---|

| 250 ton | Mechanical | 2 | Korea |

| 300 ton | Mechanical | 15 | Korea |

| 280 ton | Mechanical | 2 | Korea |

| 450 ton | Mechanical | 6 | Korea |

| 220/120/110 ton | Hybrid | 14 | Korea |

| Total | 39 machines |

This comprehensive equipment lineup ensures stable, accurate, and high-quality manufacturing performance.

2. Workforce Structure

Our skilled and experienced workforce is trained under Korean management systems, ensuring consistent and reliable production:

-

Management: 4

-

Engineering: 6

-

Direct labor: 236

-

Indirect labor: 4

-

Total workforce: 250

A strong and capable team allows the factory to maintain high productivity and quickly meet large-volume orders.

3. Production Capacity (CAPA)

The facility currently produces components for two primary product categories:

• Smartphone Components

-

Hourly output: 4,000 units

-

Daily output: 80,000 units

-

Monthly output: 2,080,000 units

• Tablet Components

-

Hourly output: 3,500 units

-

Daily output: 70,000 units

-

Monthly output: 1,820,000 units

With strong production capacity, advanced equipment, and a highly trained workforce, KB.TECH is well-positioned to handle large-scale orders while meeting strict quality and delivery standards.