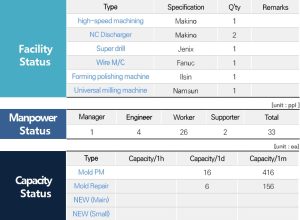

At KB.TECH, we operate a highly efficient tooling manufacturing division equipped with advanced machinery and a skilled workforce to ensure high-precision and high-quality production. Our facility includes state-of-the-art equipment such as high-speed machining centers, NC milling machines, super-drills, wire-cut machines, electric discharge machines, and precision milling machines from reputable brands including Makino, Jenix, Fanuc, Ilsin, and Namsun.

Our team consists of 33 dedicated professionals, including engineers, technicians, direct production staff, and support personnel, all working together to maintain smooth and reliable operations.

With strong production capabilities, our tooling division can achieve:

- 16 sets/day (416 sets/month) for PM tooling

- 6 sets/day (156 sets/month) for various machining and processing tasks

- Additional machining capacity for both Main and Small products

We are committed to delivering exceptional quality, precision, and productivity to meet the diverse needs of our clients.