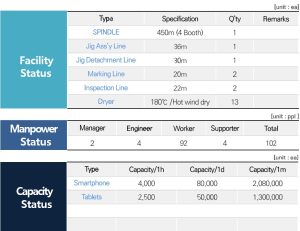

The SPINDLE Workshop at KB.TECH is a highly specialized production area designed for advanced spindle assembly, testing, and precision processing. The facility features a 450m production space equipped with 4 booths, supporting a streamlined and efficient workflow across multiple manufacturing stages.

Our workshop includes dedicated lines for assembly (36m), disassembly (30m), finishing (20m), and inspection (22m). We also operate 13 units of 180°C hot-air/thermal drying machines, ensuring optimal drying conditions and high-quality processing for all components.

The SPINDLE Workshop is staffed by 102 experienced personnel, including managers, engineers, direct production operators, and support staff. This strong team structure supports stable operations and consistent product excellence.

In terms of production capability, the workshop can achieve:

- 4,000 units/hour → 80,000 units/day → 2,080,000 units/month for Smart Buttons

- 2,500 units/hour → 50,000 units/day → 1,300,000 units/month for Tactile Buttons

With a focus on precision, reliability, and production efficiency, KB.TECH’s SPINDLE Workshop continues to deliver high-performance components that meet the demanding requirements of our global partners.